HOME

HOME  PRODUCT

PRODUCT  EPS Insulation

EPS Insulation

EPS: Thermal Insulation Material

Thermal insulation performance is 1.5 times as high as that of glass wool. EPS is also resistant to moisture and performance degradation.

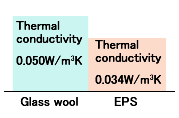

Today, glass wool is a commonly used thermal insulation material. Given that glass wool is comprised of glass fibers, over time it may become deformed, sag down in the wall, or absorb moisture and gather mold unless it is carefully applied. With its excellent thermal insulation and dampproof performances, EPS(Expanded Poly-Styrene) is expected to become the dominant thermal insulation material of the next generation. More specifically, EPS features high thermal insulation performance (thermal conductivity: 0.034 W/m・K, which is 1.5 times as high as that of glass wool (thermal conductivity: 0.050 W/m・K)), excellent dampproof performance, and long-term resistance to deformation and shrinkage. When building a new house, EPS ensures thermal insulation and energy saving performance over a long period of time.

Wall structure that incorporates EPS

Thermal insulation performance of EPS is 1.5 times as high as that of glass wool!

Back to top

High-performance and eco-friendly

EPS processed with preservatives and termite repelling agents

EPS is eco-friendly. To manufacture EPS, a hydrocarbon-based foaming agent is charged into beaded resin material to initiate preliminary foaming. The mixture is then heated to complete the foaming process. Thus, EPS is free of CFCs and HCFCs. Furthermore, EPS can be processed with flame retardants, preservatives and termite repelling agents.

Back to top

Excellent dampproof performance

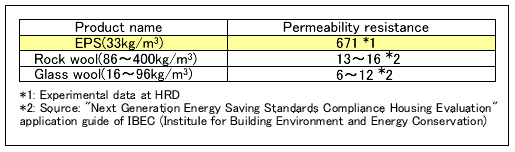

EPS also features excellent dampproof performance, which is important because EPS is incorporated in walls. Low moisture permeability prevents dew condensation, which is often the case with fibrous thermal insulation materials as they absorb moisture.

Comparison of thermal insulation materials in permeability resistance

Back to top

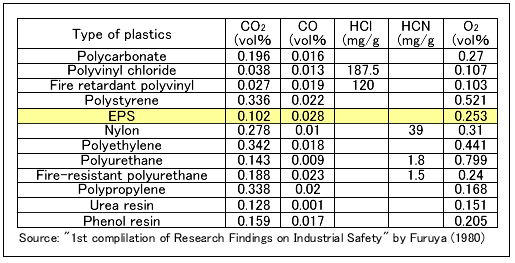

Fire-resistant and toxic-gas-free

High performance thermal insulation material EPS is different from ordinary EPS. The resin melts before it catches fire because flame retardants are added. In addition, the resin does not generate dioxin when incinerated because the carbon- and hydrogen-based material is free of chlorine. (Dioxin is generated through reaction of carbon, hydrogen and chlorine.) The document given below shows that the resin does not generate hydrogen chloride and hydrogen cyanide which result in acute toxicity. Thus, EPS ensures safety in the event of fire.

Gas toxicity test results

Back to top

HRD supplies approx. 190,000 ? of EPS to home builders in Japan annually.

In 2005, HRD supplied approx. 190,000? (for approx. 4,900 houses) of EPS to home builder in Japan. This is indicative of HRD’s capacity to ensure stable supply of high-quality, high-performance products in large quantities.

|

|

|

EPS before processing |

EPS production line |

Back to top